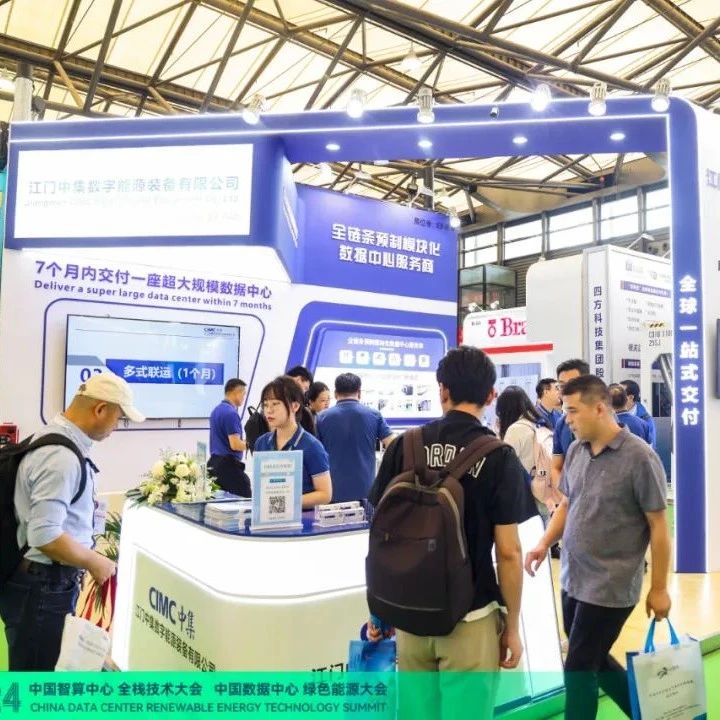

From May 22 to May 24, the 2024 Intermodal Asia was held at the Shanghai World Expo Exhibition & Convention Center. China International Marine Containers (CIMC) Group gathered with over a hundred container and intermodal companies from around the world to explore new opportunities for cooperation and industry development trends.

As an important innovation incubator and industrial base for CIMC located in the Guangdong-Hong Kong-Macao Greater Bay Area, CIMC Xinhui showcased its self-developed automatic hinge flatracks and powder coating containers at the Container Park, fully displaying new R&D products and process solutions, attracting customers and visitors from different countries for consultations.

Automatic Hinge Flatracks are Upgraded

CIMC Xinhui adheres to the corporate philosophy of creating new value for customers. Through continuous innovation and optimization of its automatic hinge patent technology, it has successfully launched a series of efficient, stable, and reliable solutions for the transportation of extra-tall and non-standard cargoes.

Compared with conventional flatracks, the 40' Domino Flatracks Type (18) brought by CIMC Xinhui this time has undergone technical upgrades. The telescopic columns are height-adjustable, achieving external heights of 10'6", 12', and 13'6" through telescopic columns, which are suitable for transporting extra-tall out-of-gauge (OOG) cargoes such as engineering machinery on container ships.

The end walls can be erected or folded manually, which are flat as the floor to be used as a 40' platform container. When fully loaded, the end walls can facilitate multi-layer stacking, fully utilizing storage space and enhancing cargo capacity utilization.

During return transport, after folding the end walls, four containers can be linked together form an 8'6" high transport module, which can be hoisted as a whole. This not only saves on the cost of returning empty containers but also conserves storage space. In addition, the 40' Domino Flatracks Type (18) is equipped with an automatic reset lock block, which automatically locks when the end walls are erected, preventing forgetting to lock.

During the exhibition, CIMC Xinhui once again showcased the process and technological advantages of powder coating containers to the audience and customers.

Powder green container technology, as a technological achievement of CIMC Group's green and sustainable development of containers, will completely solve the high pollution dilemma in the container coating process. Based on an annual output of 3 million TEU containers, if the full powder coating technology is fully applied, it can annually reduce VOCs by 14,000 tons, paint wastewater by 703,000 tons, and paint residues by 51,000 tons, reducing greenhouse gas production by 802,000 tons.

This will fundamentally achieve "clean production" of zero waste gas, zero wastewater, and zero waste residue in the coating process, with better quality, lower costs, and full HSE compliance, contributing to the green development of the container industry and aiding in the achievement of the "dual carbon" goals.